- PriceNT

- Our price:NT

- Use bonus pointspt.

A hot water boiler is a heating device that heats water for the purpose of space heating in a building or facility. These boilers commonly serve both residential and commercial spaces. The boiler functions by heating water and circulating it through pipes to radiators or underfloor heating systems, providing heat to the desired areas. Fuel sources for hot water boilers typically include natural gas, oil, electricity, or propane. The operation of the boiler is controlled by a thermostat to maintain the desired temperature. These boilers can also provide domestic hot water for household needs.

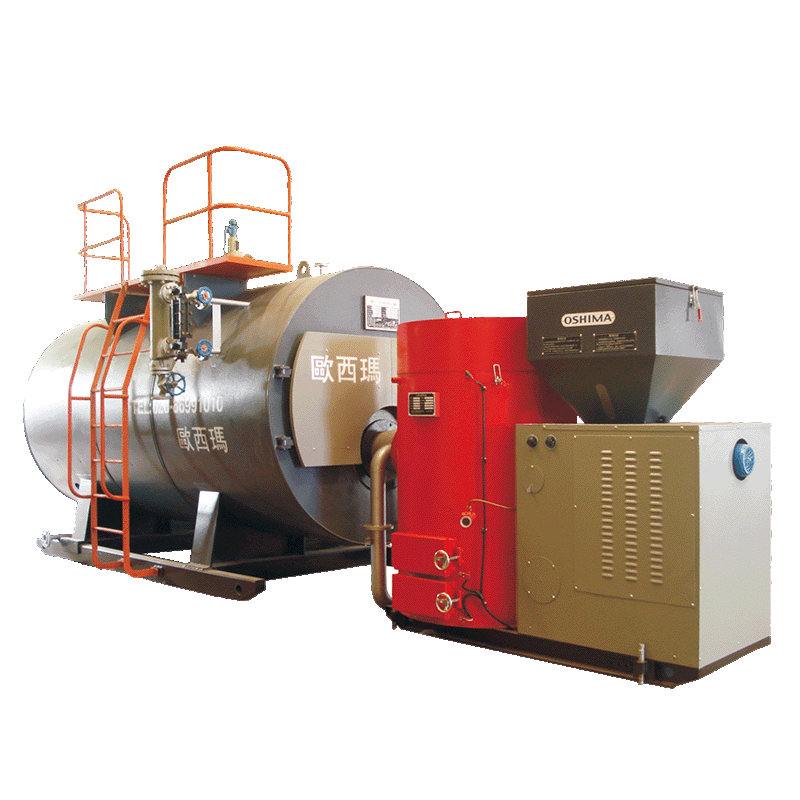

Hot water boilers fall into two categories: direct hot water boilers and indirect hot water boilers. A direct hot water boiler heats the water within the boiler itself through a heat exchanger, which transfers heat directly from the combustion process. These boilers have a simpler design, potentially making them more suitable for certain applications with lower hot water demand.

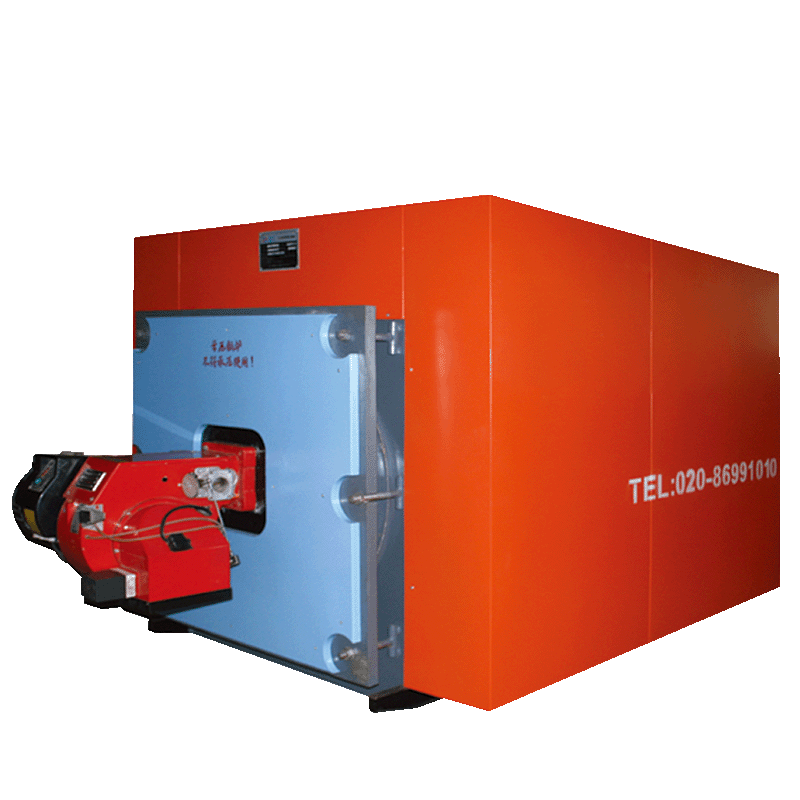

Atmospheric hot water boilers are a type of direct hot water boiler that operate at or near atmospheric pressure. They are open to the atmosphere, relying on natural convection for water circulation. This type of boiler is often used in smaller residential or commercial settings due to its simple design and inherent safety from the absence of pressure. However, since the water is exposed to the atmosphere, it can evaporate over time, requiring periodic water replenishment. Another concern is the issue of scaling, which can affect heat exchange efficiency and lifespan.

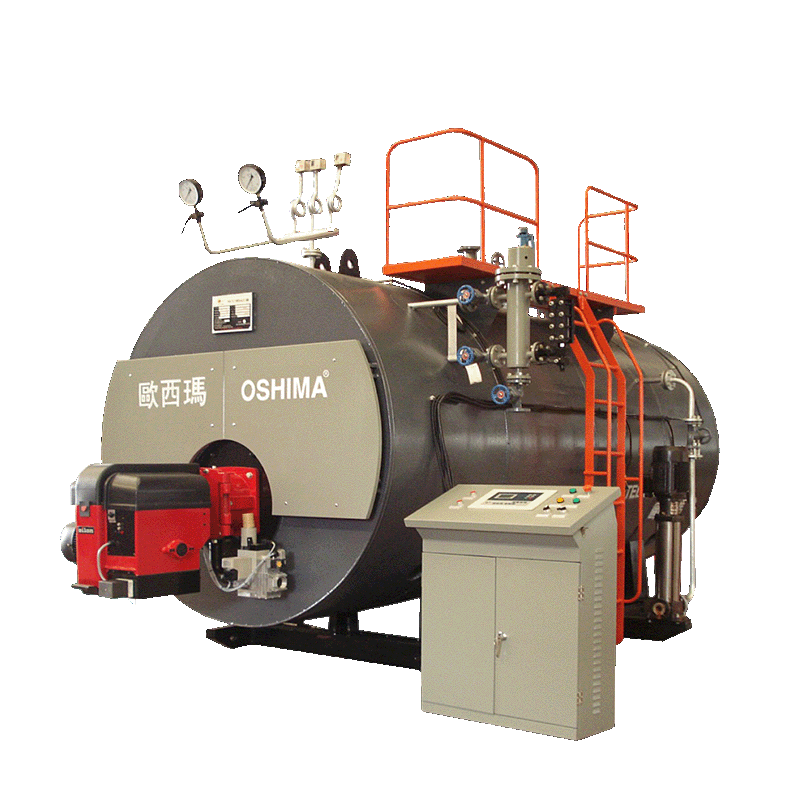

In contrast, pressurised hot water boilers operate within a closed system, keeping the water away from direct atmospheric exposure. This allows them to deliver hot water at higher temperatures, making them more suitable for larger installations or settings where higher water temperatures are needed.

It's important to note that while hot water boilers are generally more energy-efficient than steam boilers, regular maintenance is essential for optimal performance and longevity. This includes monitoring water levels, addressing scaling issues, and ensuring the system is functioning at its best.

Combustion system- 100% corrugated furnace with large combustion chamber

Advanced engineering- Thermal efficiency ≥92%

- Automatic control system

Green and low-carbon- National manufacturing standards-compliant

Investment cost- Auto-feeding system reduces human intervention

左右滑動看表格

左右滑動看表格| Model | |||||||||||

| CWNS 0.45 | CWNS 0.7 | CWNS 1.05 | CWNS 1.4 | CWNS 1.75 | CWNS 2.1 | CWNS 2.8 | CWNS 4.2 | ||||

| Specification | Heating output | kW | 465 | 698 | 1047 | 1398 | 1745 | 2097 | 2796 | 4194 | |

| *104 Kcal/h | 40 | 60 | 90 | 120 | 150 | 180 | 240 | 360 | |||

| Rated inlet and outlet temperature | ℃ | 95/70 | |||||||||

| Design exhaust temperature | ℃ | <220 | |||||||||

| 25℃ difference hot water output | L/h | 16000 | 24000 | 36000 | 48000 | 60000 | 72000 | 96000 | 144000 | ||

| Design thermal efficiency | % | ≥90 | |||||||||

| Opacity of smoke | Ringelmann chart | <1 (Comply with China national regulations) | |||||||||

| Fuel consumption | liquefied petroleum gas | Nm³/h | 20.3 | 30.3 | 45.5 | 60.6 | 75.8 | 91 | 121.3 | 182 | |

| Natural gas | Nm³/h | 51.8 | 77.6 | 116.3 | 155.1 | 193.8 | 232.6 | 310.2 | 465.2 | ||

| City gas | Nm³/h | 111.2 | 166.8 | 250 | 333.5 | 416.7 | 500 | 666.8 | 1000 | ||

| Power | Volume | 50HZ.V | 220 | 380 | |||||||

| Burner gas | kW | 0.55 | 1.1 | 1.5 | 2.2 | 3.0 | 5.0 | 7.5 | 13.5 | ||

| Overall size | Weight without water | kg | 1220 | 1500 | 2460 | 3242 | 3950 | 4660 | 6543 | 10050 | |

| Weight with water | kg | 1880 | 2430 | 3160 | 4400 | 6150 | 7020 | 10940 | 14000 | ||

- Our price:NT

- PriceNT