- PriceNT

- Our price:NT

- Use bonus pointspt.

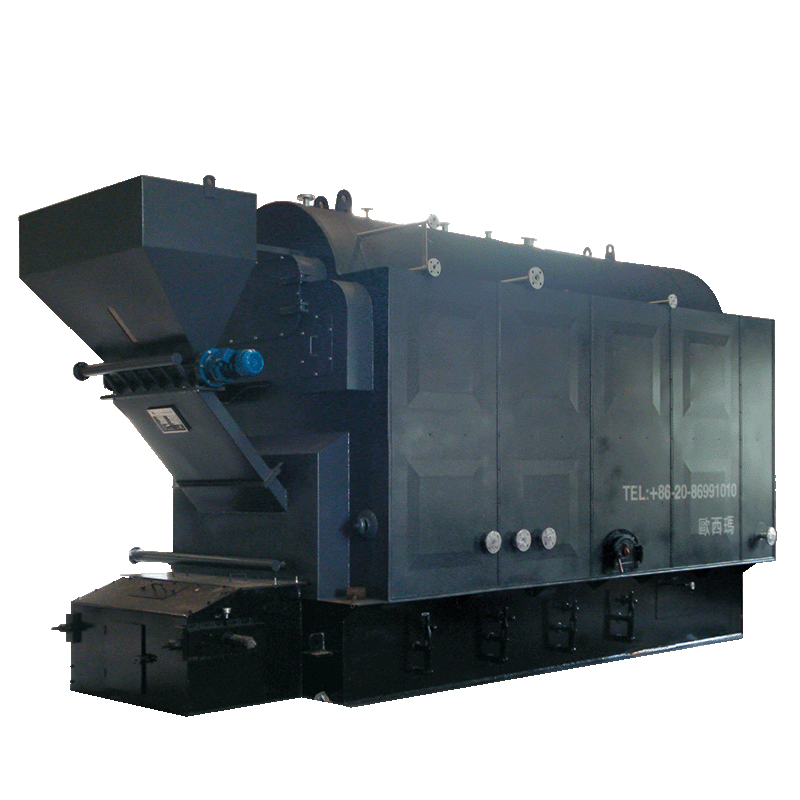

Chain grate boilers are an industrial heating solution that allows for efficient, continuous operation by moving fuel through the boiler on a conveyor belt-like grate. As the fuel progresses, it ignites and burns, generating heat to produce steam from the water within the boiler. This can be achieved either directly (in fire tube boilers) or indirectly (in water tube boilers).

However, it's important to note that chain grate boilers lack the capacity for in-furnace desulfurization, a feature present in fluidized bed boilers. This means that they emit sulfur oxides (SOx) in the flue gas, contributing to atmospheric pollution. Moreover, they can struggle with inconsistent combustion and adapting to different types of coal, affecting their efficiency. Lastly, high furnace temperatures in these boilers can lead to the production of nitrogen oxides (NOx), another pollutant that can negatively impact the environment. Regular maintenance is also essential to prevent the build-up of ash and other combustion by-products that can impact efficiency.

These boilers have one drum, which houses the water and steam throughout the combustion process. The single-drum tends to have a simpler construction, which can make it easier to install and maintain. However, single-drum designs may be less efficient at heat recovery compared to double-drum boilers due to their smaller capacity of steam generator space.

Simply word, think of this like a one-pot cooking setup. All the action - water heating and steam creation - happens in one "pot" or drum. This makes it compact and easy to handle. It's great for smaller spaces or places that don't need a lot of heat.

Bioparticle flexibility- Biomass pellets, rice husks, corn cobs, wood chips, etc

Advanced engineering- Thermal efficiency ≥82%

- Automatic pressure, temperature and water level controls

Green and low carbon footprint- National manufacturing standards-compliant

Investment cost- Quick on-site installation

左右滑動看表格

左右滑動看表格| Model | ||||||||

| DZL(W)1-1.0-BMF | DZL(W)2-1.25-BMF | DZL(W)3-1.25-BMF | DZL(W)4-1.25-SC|| | DZL(W)6-1.25-M | ||||

| Speification | Rated evaporation | t/h | 1 | 2 | 3 | 4 | 6 | |

| Rated steam pressure | MPa | 1 | 1.25/1.6 | |||||

| Rated steam temperature | ℃ | 184 | 193/204 | |||||

| Rated water inlet temperature | ℃ | 20 | 20/105 | |||||

| Design thermal efficiency | % | >82 | ||||||

| Heat of combustion | kcal/kg | 4000 | ||||||

| Fuel consumption | kg/h | 190 | 380 | 570 | 770 | 1140 | ||

| Blower | GG1-15 | GG2-15 | GG4-15 | GG6-15 | ||||

| Fan | GY1-15 | GY2-15 | GY4-15 | GY6-15 | ||||

| 2nd fan | CZ900W | CZ1100W | 9-19-4A | 9-19-4.5A | ||||

| Governor box type | GP-5P | GP-5PA | GP-10P | |||||

| Slag way | Shave plate-type/ Spiral | |||||||

| Precipitator | Cyclone dust removal/Water film dust removal | |||||||

| Heated surface | ||||||||

| Ontology | m³ | 30 | 58 | 77 | 93 | 170.5 | ||

| Steel economizer | m³ | / | 32 | |||||

| Economizer | m³ | 18.48 | 28.16 | 42.24 | 52.8 | 104.6 | ||

| Air preheater | m³ | / | 36 | 40 | 62.56 | |||

| Pump | Input power | kW | 3 | 4 | 4 | 7.5 | 7.5 | |

| Pipe | Main steam valve diameter | DN | 50 | 80 | 100 | 125 | ||

| Water inlet diameter | DN | 25 | 40 | |||||

| Safety valve diameter | DN | 50 | 40*2 | 50*2 | 80*2 | |||

| Blowoff valve diameter | mm | 40 | 50 | |||||

| Chimney | Φ | 300 | 400 | 450 | 500 | 600 | ||

| Overall size | Weight | t/h | 13.6 | 22.8 | 23.5 | 28.5 | 42 | |

| Length | m | 4.6 | 5.85 | 6 | 6.2 | 7.3 | ||

| Width | m | 2 | 2.55 | 2.66 | 2.76 | 3 | ||

| Height | m | 3.1 | 3.37 | 3.5 | 4 | 4.2 | ||

- Our price:NT

- PriceNT