- PriceNT

- Our price:NT

- Use bonus pointspt.

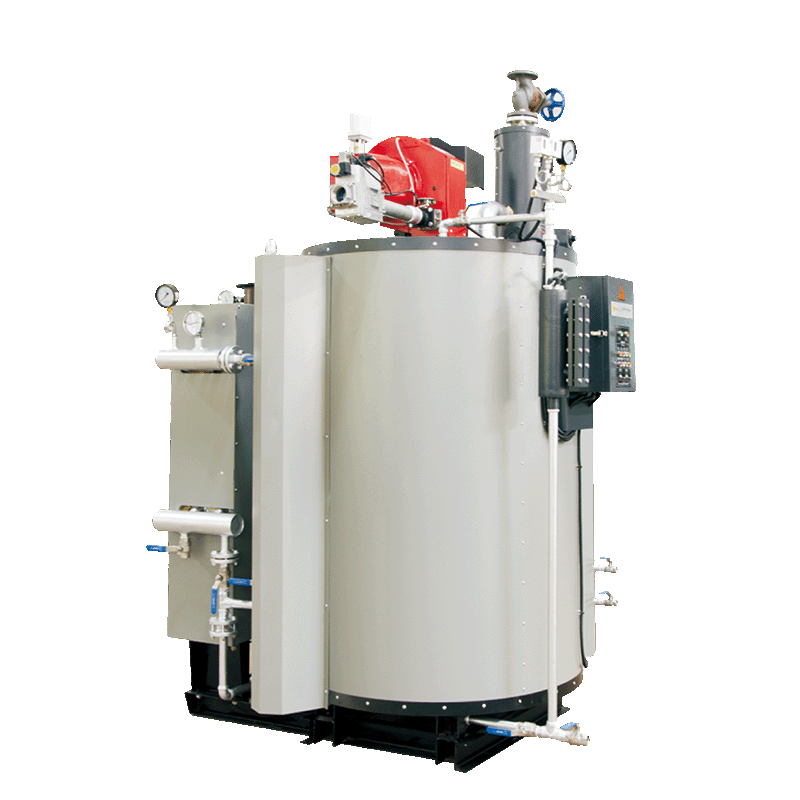

Condensing steam boilers elevate the efficiency bar by making smart use of heat energy that non-condensing boilers let slip away. Unlike the non-condensing variants, condensing steam boilers feature one or more large heat exchangers that make the most of the heat produced during combustion.

Operating at lower temperatures compared to non-condensing boilers, condensing steam boilers assure efficient heating without the excessive heat. This lowered temperature operation also contributes to the longevity of the system, reducing the wear and tear that higher temperatures can cause.

One of the significant drawbacks of non-condensing boilers is the loss of heat during the venting of combustion gases. These gases, rich in latent heat, are expelled through the flue, leading to wastage of potential heat energy. In contrast, condensing boilers reclaim this heat by directing these gases through condensing heat chambers, providing a second opportunity to extract heat, thus optimizing efficiency.

While the initial installation cost of condensing boilers may be higher, the long-term benefits in terms of lower utility bills and efficient heating systems often outweigh the upfront expenditure. On the other hand, while non-condensing boilers may seem like a budget-friendly option initially due to their lower installation cost, they could prove more expensive in the long run due to higher energy consumption and less efficient operation.

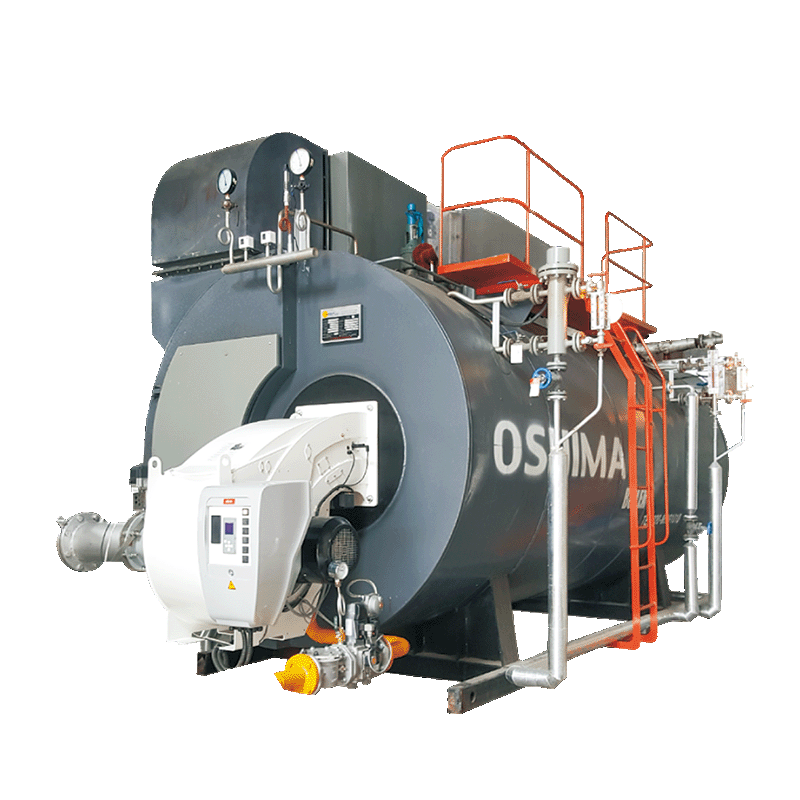

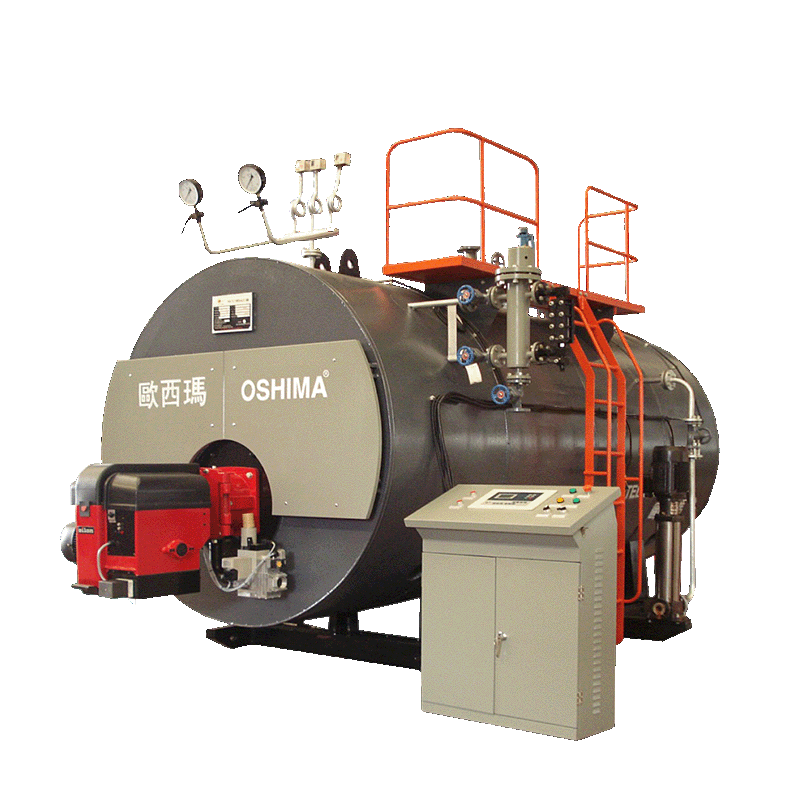

WNS (LN) is fitted with a corrugated furnace that is positioned in the lower part of the boiler. It adopts a two-pass flue gas condensing design and the amount of soot emitted complies with national emission requirements. The horizontal internal combustion two-pass wet-back structure consists of the corrugated furnace as the first pass, and smoke tubes with helical internal ribs as the second pass. The back tube plate of the boiler is not directly affected by the high-temperature flue gas, which leads to improved operating conditions and significant energy saving.

The gas transported by the gas boiler pipelines serves as energy requiring no additional gas storage facility. The design improves on-site working conditions, significantly reducing labour intensity. It saves space and reduces operating and labour costs.

In terms of maintenance, the combustion structures of hot water boilers and gas boilers are relatively simple, which means there are fewer components to maintain or repair. If the recovery rate of the condensing boiler is increased by 50%, the boiler efficiency can increase by approximately 5 to 6%, which makes it the best option for efficient use of resources. Not only heat is recovered, the consumption of water and chemicals are also reduced. At the same time, less harmful gases are emitted, thus, reducing environmental pollution as a result. This boiler has been gaining increasing popularity in many industries.

Complete combustion system- 100% corrugated furnace with large combustion chamber

Engineered for excellence- Thermal efficiency ≥99%

- Automatic control system

Green and low carbon footprint- National manufacturing standards-compliant

Investment cost- Auto-feeding system reduces human intervention

左右滑動看表格

左右滑動看表格| Model | |||||||||

| WNS1-1-Q(LN)、Y | WNS2-1.25-Q(LN)、Y | WNS3-1.25-Q(LN)、Y | WNS4-1.25-Q(LN)、Y | WNS6-1.25-Q(LN)、Y | WNS8-1.25-Q(LN)、Y | WNS10-1.25-Q(LN)、Y | |||

| Specification | Rated evaporation | t/h | 1 | 2 | 3 | 4 | 6 | 8 | 10 |

| Input power | kW | 4.5 | 9.5 | 10.1 | 20 | 24 | 31.7 | 38.5 | |

| Rated steam pressure | MPa | 1.0/1.25 | 1.25/1.6 | ||||||

| Rated steam temperature | ℃ | Room temperature 20℃ (enter the condenser), the water temperature after deoxygenating will be 104℃ | |||||||

| Design exhaust temperature | ℃ | ≤60 | |||||||

| Boiler full water volume | m³ | 2.55 | 3.8 | 4.3 | 6.14 | 7.36 | 10.6 | 13.5 | |

| Design thermal efficiency | % | 101(Converted by calorific value of low fuel level) | |||||||

| Heated surface | Ontology | m2 | 22.82 | 44.6 | 69.4 | 75.2 | 119 | 144.43 | 181.4 |

| Economizer | m2 | 18.68 | 29.23 | 43.8 | 73 | 87.7 | 112.08 | ||

| Condenser | m2 | 18.68 | 29.23 | 43.8 | 73 | 105.12 | 134.5 | ||

| Fuel consumption | Gas | Nm³/h | 71 | 142 | 213 | 282 | 424 | 568 | 710 |

| Pipe | Main steam valve diameter | mm | 50 | 80 | 100 | 125 | 150 | ||

| Water inlet diameter | mm | 25 | 32 | 40 | 50 | ||||

| Safety valve diameter | mm | 50 | 65 | 50 | 50*2 | ||||

| Blowoff valve diameter | mm | 40 | 50 | 50*2 | |||||

| Chimney | Φ | 300 | 350 | 400 | 450 | 500 | 600 | 700 | |

| Overall size | Weight | t | 5.377 | 6.2 | 8 | 11 | 14.5 | 19 | 25 |

| Length | mm | 3855 | 4600 | 4080 | 5380 | 6050 | 6637 | 7550 | |

| Width | mm | 2184 | 2000 | 2500 | 2500 | 2650 | 2856 | 2950 | |

| Height | mm | 2590 | 2700 | 3154 | 3154 | 3656 | 3874 | 3851 | |

| Height after installation | mm | 2590 | 3154 | 3656 | 3874 | 3851 | |||

- Our price:NT

- PriceNT